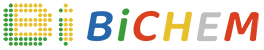

Membrane Lithium Extraction Process

01

Process Features:

1.Good technological stability

2.Continuous production with high degree of self-efficiency

3.High and stable product quality

4.High productivity

5.Low water consumption

6.Lithium yield reaches over 97%

The Membrane Lithium Extraction Process is an innovative technique that uses advanced membrane separation technology to efficiently extract lithium from salt lake brine. This method selectively permeates lithium ions through the membrane, effectively separating them from impurities. It enhances extraction efficiency and significantly reduces environmental impact, offering a more sustainable solution for lithium production.

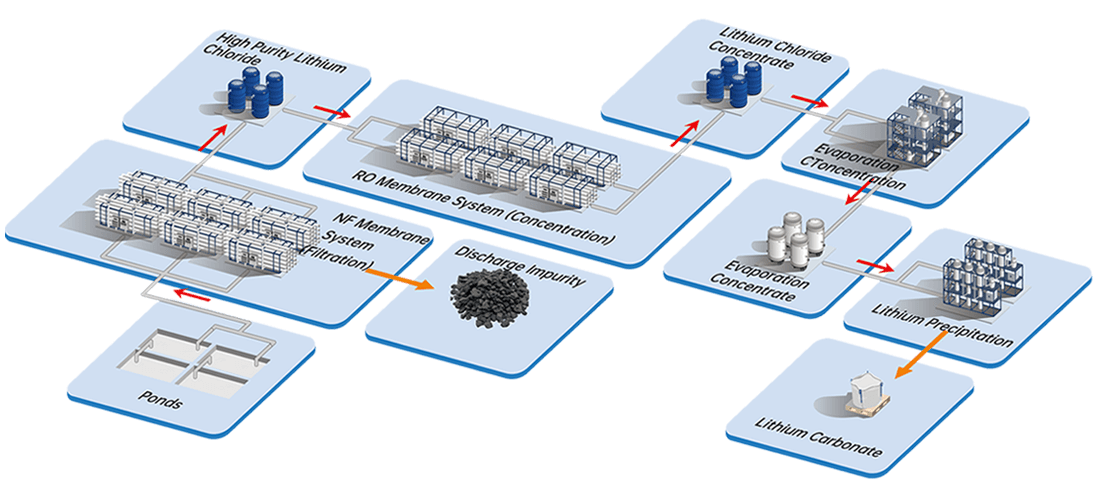

Adsorption Coupled Membrane Lithium Extraction Process

02

Process Features:

1.Efficient lithium selectivity

2.Improved lithium yield

3.Environmentally friendly process

4.Economical large-scale production

5.Adaptable to various brine

The Adsorption Coupled Membrane Lithium Extraction Process combines cutting-edge adsorption and membrane separation technologies to efficiently extract lithium from brine. This process first employs advanced adsorption materials to selectively capture lithium ions, followed by membrane separation to purify and concentrate the lithium further. This dual approach enhances extraction efficiency, ensures high product purity, and minimizes environmental impact. It offers a sustainable and effective solution for lithium production, delivering high recovery rates and optimized resource usage.

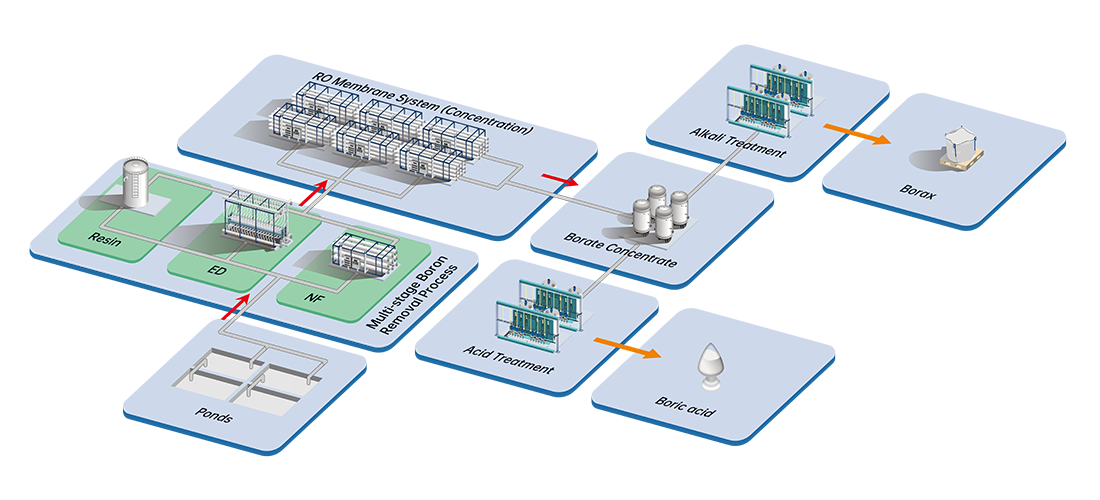

High-Purity Boric Acid/Borax Production Process

03

Process Features:

1.Boracic acid/Borax as a by-product of lithium extraction

2.Boron yield reaches over 80%

3.Low operating costs

4.Stable product quality

The High-Purity Boric Acid/Borax Production Process utilizes advanced filtration and separation methods to purify boron while extracting lithium. Through acid or alkali treatment, it produces high-purity boric acid or borax, ensuring consistent quality. This dual extraction process promotes the sustainable development of brine resources.

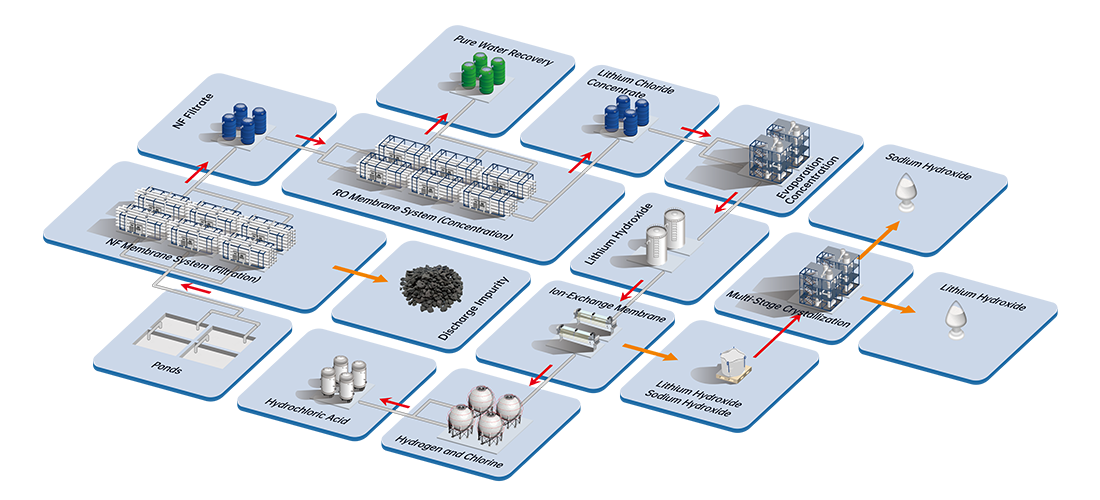

High-Purity Lithium Hydroxide Production Process

04

Process Features:

1.Low energy consumption

2.Low production cost

3.High process maturity

4.By-product hydrochloric acid

5.Strong device interchangeability

The High-Purity Lithium Hydroxide Production Process features a sophisticated series of operations that employ advanced purification techniques to ensure exceptional purity. Utilizing filtration, washing, and crystallization, this method effectively removes impurities, delivering high-quality lithium hydroxide. This efficient and sustainable approach ensures the production of high-quality lithium hydroxide, suitable for demanding applications in the high-tech industry.

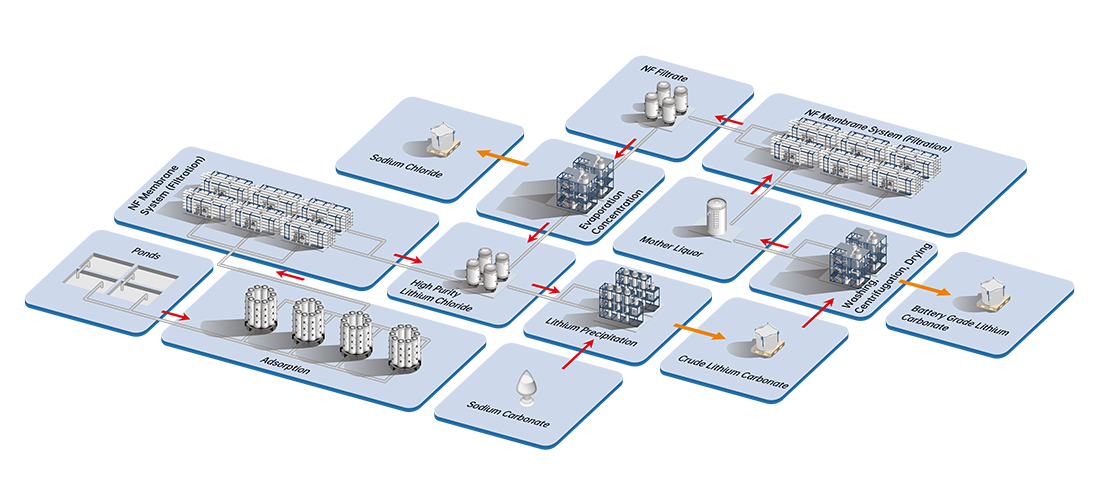

Graded Crystallization Process for High-Purity Lithium Carbonate Process

05

Process Features:

1.Lithium yield reaches over 95%

2.Low consumption of sodium carbonate

3.Low water and energy consumption

The Graded Crystallization Process for High-Purity Lithium Carbonate Process leverages multi-stage filtration and crystallization to produce high-purity lithium carbonate, essential for advanced technology applications. By sequentially precipitating lithium carbonate under precisely controlled conditions, this method effectively isolates and removes impurities at each stage. The result is a superior quality product, ideally suited for use in high-performance batteries and precision electronics. This efficient and environmentally conscious approach ensures exceptional purity and consistent output, aligning with industry standards for sustainability and quality.

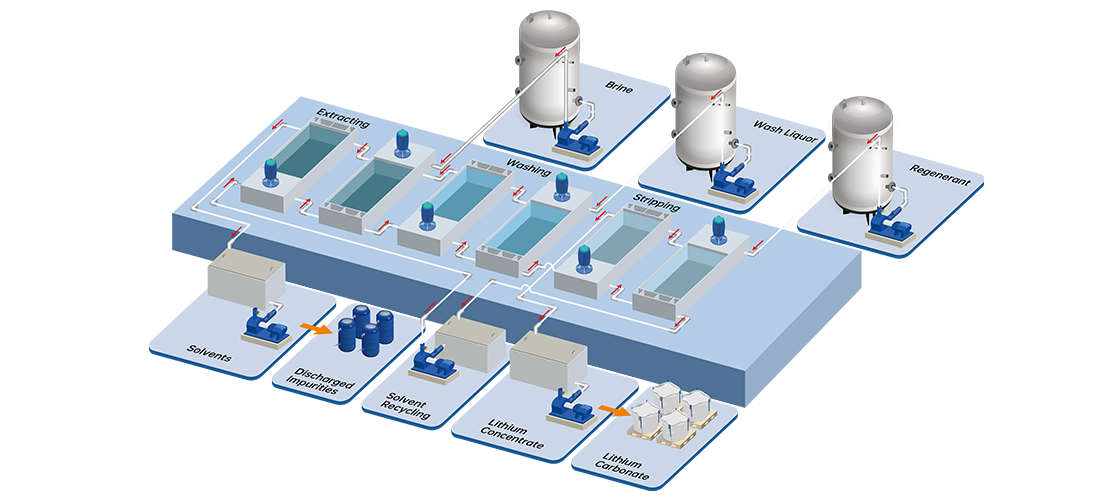

Solvent LithiumExtraction Process

06

Process Features:

1.Minimal energy use with pumps and motors

2.Water saving, ideal for water-scarce areas

3.Precise ion separation

4.Lithium yield exceeds 95%

5.High-purity production with over 28g/L lithium and low impurities

6.Simple, stable process ensures reliability

The Solvent Lithium Extraction Process is a cutting-edge technique that employs selective organic solvents to efficiently extract lithium from brine. This process involves the use of highly selective solvents that bind with lithium ions, allowing for the precise separation of lithium from other minerals and impurities present in the brine. Beyond its efficiency and scalability, this method excels in conserving energy and minimizing ecological disruption. It stands out as a forward-thinking choice, combining environmental stewardship with economic practicality for industrial-scale lithium extraction.

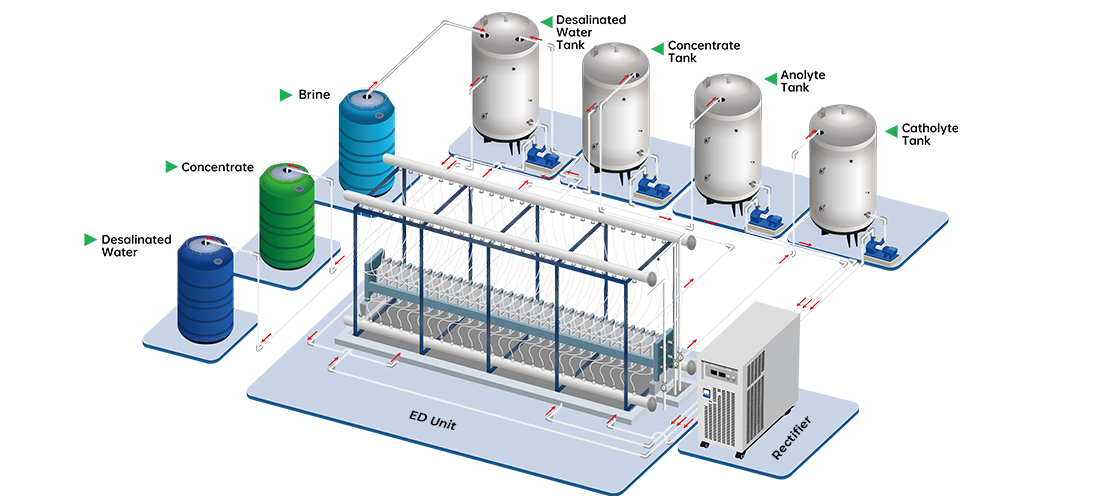

Electrodialysis (ED) Lithium Extraction Process

07

Process Features:

1.Efficient removal of boron and silicon

2.Cuts resin costs by 20%, reducing lithium loss

3.Minimizes lithium loss to 0.5%

4.Increases water recovery by 10-30%

5.Extends filter life and stabilizes the system

6.Reduces silicon contamination, improving purity

7.Enables lithium concentration and boron removal together

8.Lowers the need for evaporation stages

The Electrodialysis Lithium Extraction Process is an innovative technology that leverages an electric field to selectively move lithium ions through ion-exchange membranes, effectively separating them from other ions in salt lake brine. This approach concentrates lithium efficiently while ensuring a high level of purity in the final product. Notably, the process operates with minimal chemical input and a lower environmental footprint, offering a forward-looking solution for scalable, energy-conscious lithium production.