Bichemical Technology Ltd (BICHEM) is a global leader in direct lithium extraction technologies, providing comprehensive solutions across integrated plant services, operations and maintenance. Our patented technologies cover lithium chloride, lithium carbonate, lithium hydroxide, lithium metal, borax, and boric acid.

BICHEM leads with innovative and exclusive engineering expertise throughout the entire lithium extraction process from salt lake brines. Our innovative processes enable the production of high-purity lithium carbonate from complex brines, establishing our plants as industry leaders in lithium recovery, product quality, cost efficiency, and intelligent operations.

Our team, rich in expertise and experience, is committed to continuous innovation through scientific research, pilot testing, and engineering practice.BICHEM is dedicated to delivering top-tier solutions, propelling industry growth, and creating sustainable value for our clients.

5+

Global R&D Centers

300+

Professionals

20+

Projects

90%+

Lithium yield

100,000+t/a LCE

Achieved Production Scale

80,000+t/a LCE

Operational Production Scale

150,000+t/a LCE

Under-construction Production Scale

In 2002, our team designed Singapore's first desalination plant. Over the next 20 years, we grew into one of the world’s leading desalination teams, specializing in advanced membrane technology.

In 2004, our team pioneered in the chlor-alkali industry by utilizing underground brine as a raw material. We applied PTFE microfiltration to purify the brine and advanced nanofiltration membrane technology to produce high-purity sodium chloride, a critical component in chlor-alkali production.

In 2006, our team innovated and built up a lithium chloride separation and concentration membrane system for China’s first large-scale lithium extraction project from brine, achieving an annual production capacity of 10,000 tons LCE.

In 2014, our team launched China's first underground brine refining project in the soda ash industry. Using nanofiltration technology, we effectively removed calcium, magnesium, and sulfate ions from the brine, producing refined sodium chloride directly for soda ash production.

In 2016, we developed an adsorption-coupled membrane treatment solution, enabling successful large-scale lithium carbonate production with a capacity of 10,000 tons LCE per year.

In 2017, we entered the global bid for a 30,000-ton battery-grade lithium carbonate project at Salar de Uyuni, Bolivia, achieving the top technical ranking in two consecutive evaluations.

In 2018, we introduced the "Boron-Lithium Co-Extraction" process technology, a breakthrough approach that enabled efficient large-scale lithium carbonate production. This innovative process supported the successful operation of a 10,000-ton capacity project, optimizing resource use and enhancing production efficiency.

In 2019, we joined the Salar de Coipasa project in Bolivia, targeting annual production of 500,000 tons of potash, 60,000 tons of lithium hydroxide, 60,000 tons of boric acid, 10,000 tons of sodium bromide, and 10,000 tons of bromine. We secured the contract with top global rankings in both commercial and technical evaluations.

In 2020, we introduced a membrane-based lithium extraction process for carbonate-type salt lakes and successfully completed process validation for a 10,000-ton lithium carbonate project.

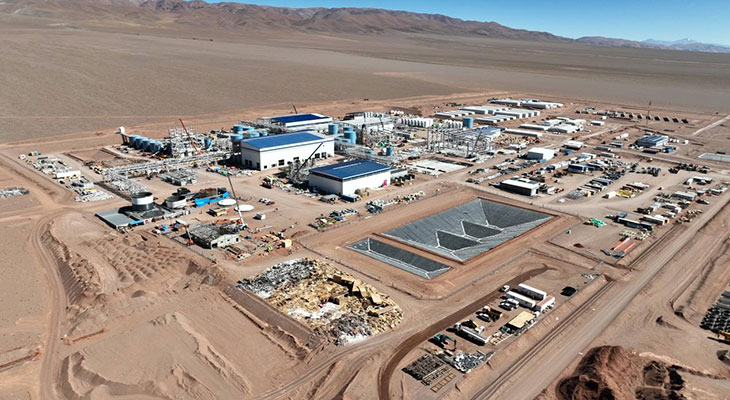

In 2022, we refined our lithium extraction process from raw brine using advanced multi-membrane technology, achieving a successful scale-up to the design capacity of 20,000 tons of battery-grade lithium carbonate.

In 2022, we were entrusted with the design of the second phase of the Centenario-Ratones lithium plant in Salta Province, Argentina, targeting an annual production of 25,000 tons of battery-grade lithium carbonate.

In 2022, we secured a contract for the Arizaro Salt Lake project in Salta Province, Argentina, with a target annual production of 50,000 tons of lithium carbonate. Our scope includes design, construction, commissioning, and operational management.

In 2023, we applied adsorption-coupled membrane technology in our Boron-Lithium Co-Extraction project, achieving full production capacity. This project yields 20,000 tons of battery-grade lithium carbonate and 10,000 tons of borax annually.

In 2023, our team successfully designed and constructed a facility with an annual capacity of 15,000 tons of battery-grade lithium carbonate. This facility utilizes an advanced adsorption-coupled membrane process, with our team overseeing every stage from construction through to full-scale production operations, ensuring efficiency and high product purity.

In 2024, our advanced solvent-based lithium extraction process successfully passed validation tests and was fully implemented, with a 10,000-ton battery-grade lithium carbonate facility now constructed and in full production as of October. This achievement marks a major advancement in efficient, high-purity lithium extraction.

In 2024, we launched the Membrane Manufacturing R&D Center in Germany, the Filtration Technology Innovation Center in Japan, and the Latin America Salt Lake Center in Chile. These strategic centers enhance our capabilities in lithium extraction, supporting both technological research and market expansion efforts worldwide.

Operational Innovation

Focused on Production Excellence

Strategic Innovation

Driven by Evolving Scenarios

Pioneering Innovation

Propelled by Industry Expansion

BICHEM Group

Client